Construction & Agricultural Vehicles

Smart and rugged solutions for heavy-duty vehicles

Tria designs and manufactures embedded compute modules, systems and HMIs for OEMs in the construction, agricultural, and transport sectors.

We work closely with customers to overcome technical challenges, accelerate innovation, and deliver durable, future-ready vehicles built for real-world environments.

With decades of experience in design and manufacturing, we combine trusted platform technologies, strong partnerships, and advanced production capabilities to simplify development, reduce risk, and speed up time to market.

Tria supports OEMs with:

- Embedded compute modules

- Embedded systems

- HMIs (human machine interfaces)

- Software, OS and BIOS support

Explore our range of technologies for heavy-duty vehicles

Tria designs standard compute modules and kits that are well-suited for construction and agricultural vehicle applications. Explore some examples below or view our full range. All modules can be customized or used as starting points for full system designs.

CPU Modules

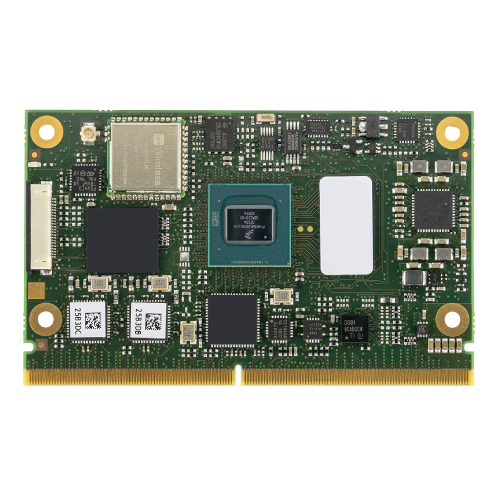

TRIA SM2S-IMX8PLUS (NXP® Cortex®-A53)

High-performance, low-power SMARC module with NXP i.MX 8M Plus processor. Features quad Cortex-A53 cores, real-time Cortex-M7, GPU, and 2.3 TOPS ML accelerator. Ideal for edge AI and multimedia applications with dual Gigabit Ethernet, PCIe Gen 3, and onboard wireless.

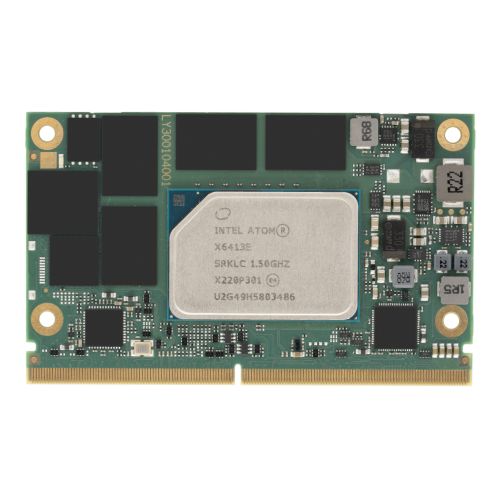

TRIA SM2S-EL (Intel Atom® Elkhart Lake)

A SMARC module built on Intel Atom “Elkhart Lake” processors, offering up to quad-core performance, triple 4K display support, dual Gigabit Ethernet with TSN, and CAN-FD. Designed for extended temperature range and 24/7 operation, it’s ideal for mission-critical applications that demand a reliable, high-performance compute base.

Explore our standard module ranges

Customization

Tria’s complete Computer-on-Modules act as ready-to-use cores that slot straight into a full-custom board designs for any application. This helps OEMs cut development time and accelerate time to market.

We also support custom:

- Carrier boards

- ARM-based single board computers

- BSPs and BIOS

- OS and application software

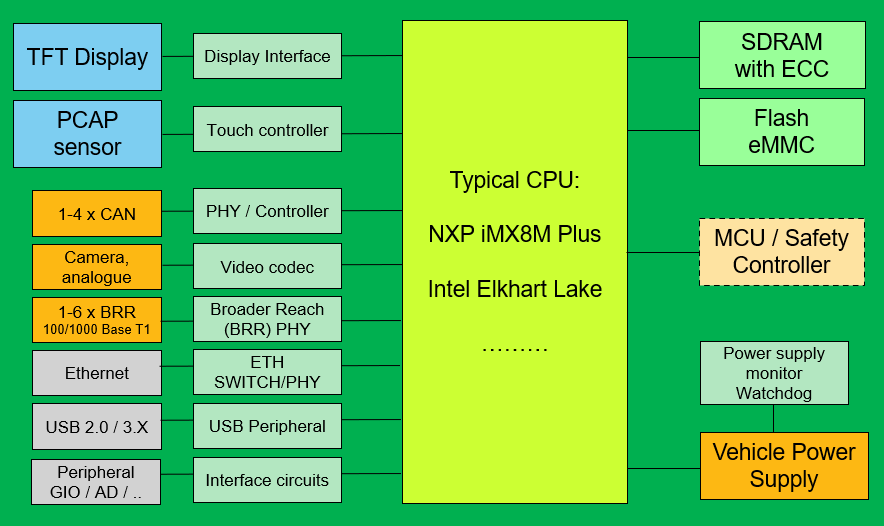

A typical hardware concept for construction and agricultural vehicles

Actual configuration may vary based on customer requirements

Functional Safety

At Tria, we design with FuSa in mind from day one, covering essential safety functions across input, output, and system integrity:

- Reliable touch input

- Consistent display output

- Clear and accurate acoustic warnings

- High-integrity camera input

- Storage integrity

- Continuous monitoring of supply voltage, clocks, and software execution

Display innovation

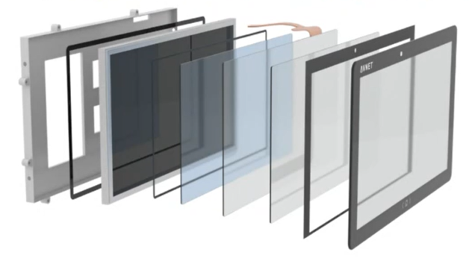

Tria works with a wide ecosystem of Tier 1 display manufacturers to deliver custom, application-ready display stacks. Most construction and agricultural vehicle projects require a fully integrated approach that combines display, touch interface, and cover lens in a single bonded solution.

With R&D and engineering based in Germany, and close partnerships with key touch, driver, and second-tier display integrators, we help OEMs achieve the right balance of performance, durability in harsh conditions, and cost.

For accelerated development without sacrificing quality, standardized platforms like SimpleFlex support faster display integration and time to market

Typical display and touch specifications

For vehicles exposed to tough terrain, vibration, extreme weather, or other demanding conditions, these are the HMI specifications we typically work with:

Display size: 5”–12.8” (varies by UI, function, and driver cabin)

Brightness:800–1100 cd/m² high-brightness for outdoor use

Touch:PCAP (resistant to 150V/m EMI, water-resistant)

Cover lens:AG / AR / AF coating, IK ≥7 (mechanical impact protection)

UV protection:Shielded against UV exposure

Bonding:Optical bonding (OCR / OCA) for optimal sunlight readability

Operating temperature:-30°C to +85°C (extended temperature range)

Shock & vibration: Engineered for high shock and vibration resistance

Longevity:7+ years (second source for the cell is crucial)

Case Study: An HMI for roadwork machines

A global leader in construction equipment needed a fully custom HMI family for its next-generation roadwork machines. The solution had to perform reliably in harsh environmental conditions.

Our Approach

Tria developed a modular, fully custom HMI system for seamless cabin integration and built to withstand harsh environmental conditions. It featured:

- 5”, 7”, and 10.1” high-brightness TFT displays (1000 cd/m²) with optically bonded PCAP

- ARM-based modular SMARC Computer-on-Module

- Long-term availability (10–15 years) for extended product lifecycle

The Result

Tria’s ultra-rugged, modular HMI improved usability, increased efficiency, and reduced costs across its customer’s entire product line.

Case Study: An HMI for agricultural machines

A leading agricultural OEM needed a rugged HMI with a modern interface, high brightness, and powerful graphics to control vehicle functions and display camera feeds in its new series of driver cabs.

Our Approach

Tria developed a fully custom HMI system with a separate CPU unit and up to two display units, designed for seamless integration into the cabin. It featured:

- 12.1” high-brightness TFT display (1000 cd/m²) with optically bonded PCAP

- x86-based single-board computer

- Long-term availability (10–15 years) for extended product lifecycle

The Result

By integrating Tria’s modern, touch-based HMI, our customer strengthened its market position while increasing efficiency, profitability, and sustainability across its latest generation of agricultural vehicles.

Our technology partners for construction and agricultural vehicles

We work closely with the world’s leading processor, component, software and specialist technology partners to deliver the best possible solutions for OEMs in the sector, including:

Designed and manufactured in Europe, available worldwide.

Empower your construction and agricultural vehicles with Tria

We can support you with:

- Designing versatile systems for multiple vehicle types and cabins

- Integrating key CPUs, interfaces, and DTC functionality

- Engineering for extreme environments (temperature, shock, vibration, EMC, sunlight)

- Meeting or exceeding industry standards

- Achieving functional safety compliance for critical systems

- Securing reliable supply at SOP with zero disruption risk

- Maintaining stable, long-term product availability with minimal changes

- Delivering product longevity exceeding 10 years

- Extending service and support beyond end-of-production

- Future-proofing solutions to stay at the leading edge for three years or more